Key Factors Affecting Custom Uniform Prices: Businesses Need to Know

Businesses often wonder how custom uniform prices can vary so much. Whether you're outfitting a small team or an entire organization, understanding what affects the cost is key to making smart decisions. From material quality to order quantity, many factors come into play, and missing just one detail could mean going over budget. This guide will break down all the elements that influence custom uniform pricing.

Ready to learn how much do custom uniforms cost based on different factors? Let's dive into the key factors you need to know.

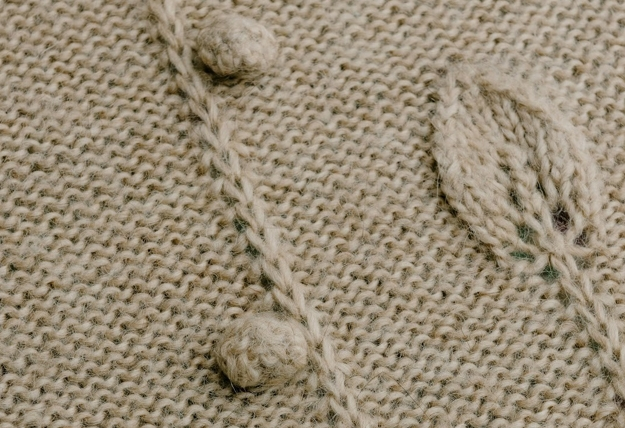

1. Fabric and Material

· Types of Fabric

The cost of the customized uniforms differs depending on the type of fabric used in the making of the uniforms. Cotton is cheaper and more comfortable to wear in the heat. On the other hand, polyester has the benefits of durability and no wrinkle formation, but it is a bit more costly than cotton. It is, therefore, possible to have fabrics that are a blend of both materials, for instance, poly-cotton, which provides both comfort and durability. Specialty fabrics, such as moisture-wicking or fire-resistant materials, can also drive up costs. The weight of the fabric, its weave, and the quality of the material used determine the final price of the uniform.

· Customization of Fabric

Businesses may need fabrics that are dyed to their brand colors, which increases the overall cost. Fabric patterns like pinstripe or checks are not easily produced, and therefore, they call for more labor and material resources, which takes the cost even higher. Additional features such as water resistance or stain resistance can add to the costs even further. Small changes in the texture of the surface, whether matte or shiny, slightly influence the cost. Businesses should factor in these customizations when budgeting for uniforms.

2. Design Complexity

· Embroidery, Printing, and Branding

Embroidery is more costly than printing as it takes more time and special equipment. For instance, a small logo that is printed on a shirt will be cheaper than having a big design, which uses several colors, on the uniform. Techniques of printing such as screen printing might be cheaper but they are not as durable as the usual washing might affect them. Embroidery or printing should therefore be chosen based on the budget and durability needs.

· Design Intricacy

The more detailed the design is, the more expensive it becomes. Complex logos or patterns take more time and money to create as compared to the basic ones. For instance, a simple name written on a garment and embroidered is cheaper than a complex design that occupies the entire back of the garment. As the complexity of the design increases, more time, skill and sometimes even different types of material is needed.

· Additional Features

Adding custom features to uniforms significantly impacts pricing. Items like custom zippers, buttons, and extra pockets increase the manufacturing time and material costs. For example, a jacket with custom zippers and branded buttons will cost more than a simple one with standard features. Businesses often opt for these extras to enhance the appearance or functionality of the uniforms but should be aware of the added expenses.

3. Order Quantity

· Bulk Orders

It is cheaper to order uniforms in bulk. This is because manufacturers are able to produce large quantities at one time, hence reducing their costs of production and, in turn, offering discounts to businesses that purchase in bulk. For example, it is more cost-effective to produce 500 uniforms in one go than to produce 50. The savings are derived from the fact that materials such as fabric and thread can be purchased in bulk at a cheaper price. This advantage is extended to the buyer. Also, fewer production runs helped save on labor and machinery costs.

· MOQs (Minimum Order Quantities)

Many custom uniform manufacturers have MOQs in order to minimize the wastage of resources on small orders. MOQs define the minimum quantity of products that a business has to purchase to be offered a lower price. For instance, if the MOQ is 100 pieces, it means that ordering fewer than 100 pieces will be costly because the supplier cannot achieve the benefits of economies of scale. This threshold ensures that the manufacturers are able to recover fixed costs such as machine setup, labor, and materials. Small businesses struggle to meet MOQs, but they can negotiate for flexibility depending on the size of the supplier.

4. Production

· Production Location

The place of production is a key factor that determines the price of custom uniforms. Purchasing uniforms from other countries where the cost of labor is cheaper can be economical. For instance, the uniforms manufactured in China, Vietnam or Bangladesh are cheaper than those manufactured in the U. S. or Western Europe. Also, the production facilities that are closer to the supplier can reduce the transportation cost. Therefore, selecting a manufacturer in the neighboring area could prove to be less expensive.

· Labor Costs

Labor costs are a direct determinant of the price of custom uniforms. This implies that, the higher the wages paid in the country, the higher the costs of production. For instance, a custom made uniform produced in the U. S. may cost more than one produced in China because of the higher wages paid to workers. Worker's skill and experience also influences the price. Custom uniform manufacturing might require more experienced workers, thus the higher price.

· Shipping and Tariff Costs

Shipping costs and the cost of tariffs also contribute to the overall cost of custom uniforms. Shipping costs can be significant when uniforms are to be shipped across borders, especially for bulk orders. For instance, the cost of shipping from Asia to North America can be steep, and this contributes to the final cost. Government-imposed tariffs and import duties also enhance the final cost. Businesses should factor in these potential costs when selecting suppliers and planning their budget to avoid unexpected expenses.

5. Product Quality

The use of high-quality fabrics that are capable of wicking moisture and quality stitching usually form part of the cost. The uniforms that are made from polyester fabric that has enhanced moisture control and durability will be more expensive. Also, extra features such as high-stress seams and company logos also contribute to the total cost. In essence, high-quality uniforms with better materials and more precise manufacturing processes lead to high costs.

It is for this reason that businesses need to consider the cost of durability and comfort against the cost of acquiring the uniforms since high quality uniforms may be cheaper in the long run. Knowledge of these factors aids in decision making of the budget and expected number of uses of the uniforms.

6. Supplier's Services

Suppliers offering design consultations or digital proofs may charge more due to their added expertise and time. Additionally, those who provide in-house embroidery or printing services typically have higher costs compared to suppliers who outsource these tasks.

Some suppliers also offer bulk ordering discounts or reduced pricing for long-term contracts. Businesses should compare these additional services to find the best value. For example, a supplier with fast turnaround times might cost more but save businesses money in the long run by reducing downtime.

Final Thoughts

An informed decision demands careful considerations of all significant aspects. Every aspect, right from the type of material used to the number of orders placed, can have a bearing on the custom uniform prices. It's essential to weigh these aspects carefully to ensure you get the best value for your investment.

Based on the above factors, a sensible decision would be Kutesmart. Kutesmart is a custom uniform manufacturer company which has been in the business as a reliable and experienced supplier. We sell a variety of apparels with MOQ of 1 piece and have a very fast turnaround time of 7 days. Our commitment to quality and customer satisfaction makes them a great choice for businesses seeking excellent custom uniforms.

FAQs

Q: Do uniform pricing models differ for various industries?

A: Yes, pricing models can vary based on industry-specific requirements. For instance, the type of fabric used for healthcare or hospitality may need to be treated with antimicrobial properties, which is different from corporate wear, hence the difference in the cost.

Q: How does the warranty or guarantee affect uniform costs?

A: Uniforms with longer warranty periods are likely to be expensive as they come with a promise of quality and longevity of the product. It can be a good investment for businesses that are in a search for long term dependable supply.

Q: What are the different types of printing methods for custom uniforms?

A: Common ways of printing include screen printing, sublimation and heat transfer printing. All methods come with their own costs. Screen printing is cheaper when dealing with bulk orders, while sublimation is used for bright, rich and full color images.

.png)